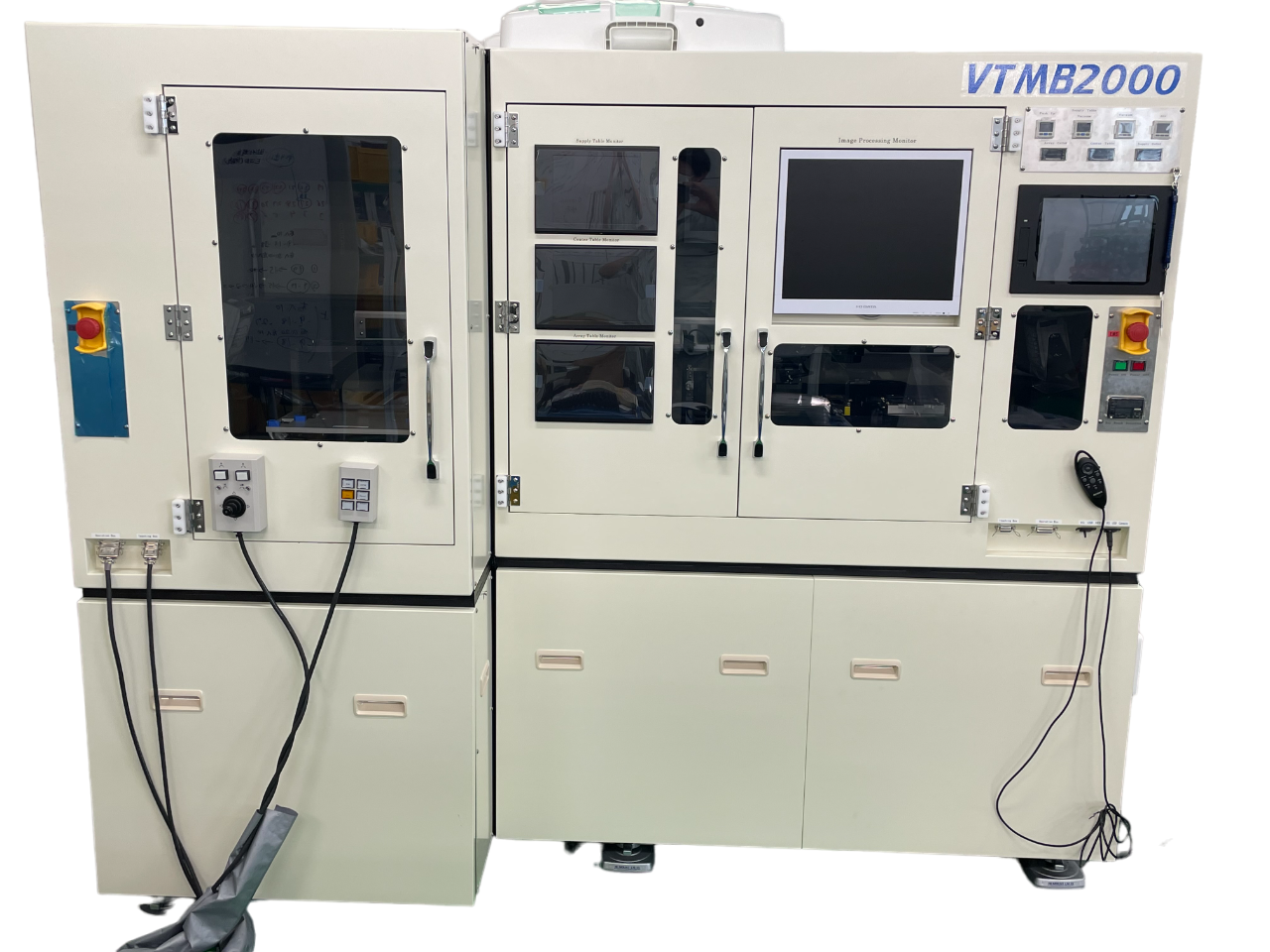

LD Bar Placer VTMB2000

on

• High Precision Bar alignment and Positioning Camera

• Operation Monitoring and NG Bar Handling - NG bars are not picked up

• Bar Length monitoring - NG Length bars are transferred to the NG tray

• Two axis robot transfer arm picks up LD bars from the alignment table and transfers them to the frame

• Ability to pick and place from a number of formats (Gel-Pak , waffle pack, grip ring or frame)

• Optimized pick-up collet to prevent laser diode damage during the pick and place

• Placement accuracy of ±5 µm

• High Throughput robust machine suitable for both R&D and mass production

• Easy operation and menu set up

• Work Type : LD Bar

• Bar Cavity : 150 um ~ 6400 μm

• Bar Length : 10 – 17mm

• Bar Thickness: 50~150μm

2.LASER BAR SUPPLY CARRIER

• Four 2- inch Gel packs or One 4 -inch Gel pack

Pickup test is required for a bar from 150 to 250um

Or • One 4 -inch waffle pack

Pickup test is required to confirm that a collet can contact a bar in the pocket. Or

• One 6- inch grip ring or One 6 inch frame

Non-adhesive (ATR) tape is required

3. LD BAR PLACEMENT CARRIER

• One 6-inch frame or One 8 -inch frame

Work area on the tape : 70×70mm (Both 6 inch and 8- inch frames)

• Placement Accuracy : X:±5um Y:±100um θ:±0.2°

4. TACT TIME

• 10 sec/chip or less

*The above is average cycle time

5. MACHINE SIZE: 1500(W) × 1200(D) × 1800(H) mm

6. MACHINE WEIGHT: Approx. 1000 Kg

7. UTILITY

• Power Supply: 100V 50/60Hz 15A

• Air: Dry Air Factory Line / Dry Air 0.4 MPa 20L / min

Laser Diode Bar Placer VTMB2000

The VTMB2000 Laser Diode (LD) bar placer is designed to pick up coated laser diode bars from a number of presentation formats and accurately place them on output frames.

Coated LD bars are automatically picked up from Gel-Pak , Grip Ring ,Waffle Pack or Frame and place in array on the output frame with placement accuracy of ±5 µm and average cycle time less than 10 seconds.

This high precision pick and place tool includes a number of design features to consistently deliver high quality LD bar placement results. Features include optimized pick-up collet to prevent damage to the laser diode during pick-and-place, high precision bar alignment and positioning and automatic monitoring and rejection of no-good bars . Additionally, the robust design comprising high quality image processor, bar supply ,bar alignment ,bar transfer and bar transfer stages. makes this machine a perfect choice for both R&D and mass production.

Coated LD bars are automatically picked up from Gel-Pak , Grip Ring ,Waffle Pack or Frame and place in array on the output frame with placement accuracy of ±5 µm and average cycle time less than 10 seconds.

This high precision pick and place tool includes a number of design features to consistently deliver high quality LD bar placement results. Features include optimized pick-up collet to prevent damage to the laser diode during pick-and-place, high precision bar alignment and positioning and automatic monitoring and rejection of no-good bars . Additionally, the robust design comprising high quality image processor, bar supply ,bar alignment ,bar transfer and bar transfer stages. makes this machine a perfect choice for both R&D and mass production.

Features

• Fully automatic Laser Diode bar pick and place • High Precision Bar alignment and Positioning Camera

• Operation Monitoring and NG Bar Handling - NG bars are not picked up

• Bar Length monitoring - NG Length bars are transferred to the NG tray

• Two axis robot transfer arm picks up LD bars from the alignment table and transfers them to the frame

• Ability to pick and place from a number of formats (Gel-Pak , waffle pack, grip ring or frame)

• Optimized pick-up collet to prevent laser diode damage during the pick and place

• Placement accuracy of ±5 µm

• High Throughput robust machine suitable for both R&D and mass production

• Easy operation and menu set up

Specification

1. WORK SUPPLY AND PLACEMENT CARRIER • Work Type : LD Bar

• Bar Cavity : 150 um ~ 6400 μm

• Bar Length : 10 – 17mm

• Bar Thickness: 50~150μm

2.LASER BAR SUPPLY CARRIER

• Four 2- inch Gel packs or One 4 -inch Gel pack

Pickup test is required for a bar from 150 to 250um

Or • One 4 -inch waffle pack

Pickup test is required to confirm that a collet can contact a bar in the pocket. Or

• One 6- inch grip ring or One 6 inch frame

Non-adhesive (ATR) tape is required

3. LD BAR PLACEMENT CARRIER

• One 6-inch frame or One 8 -inch frame

Work area on the tape : 70×70mm (Both 6 inch and 8- inch frames)

• Placement Accuracy : X:±5um Y:±100um θ:±0.2°

4. TACT TIME

• 10 sec/chip or less

*The above is average cycle time

5. MACHINE SIZE: 1500(W) × 1200(D) × 1800(H) mm

6. MACHINE WEIGHT: Approx. 1000 Kg

7. UTILITY

• Power Supply: 100V 50/60Hz 15A

• Air: Dry Air Factory Line / Dry Air 0.4 MPa 20L / min

Product Inquiry Form